1. Introduction to Teamcenter

Teamcenter today’s complicated product development landscape, managing data across departments, systems, and global locations is vital. This is where Siemens Teamcenter, a top PLM software solution, stands out. It enables companies to digitize every stage of their product lifecycle, from conception to production to support, enhancing creativity, speeding up time to market, and lowering expenses. At Hope Infotech, we specialize in delivering industry-aligned, expert-led Teamcenter online training that empowers learners to gain practical knowledge, enhance job-ready skills, and secure lucrative career opportunities in PLM ecosystems. Functional communication, organized workflows, and extensive interaction with CAD, ERP, and other corporate systems are made possible by single data backbone. Knowing may help your company stand out from the competition, regardless of your role as an engineer, product manager, or corporate decision-maker.

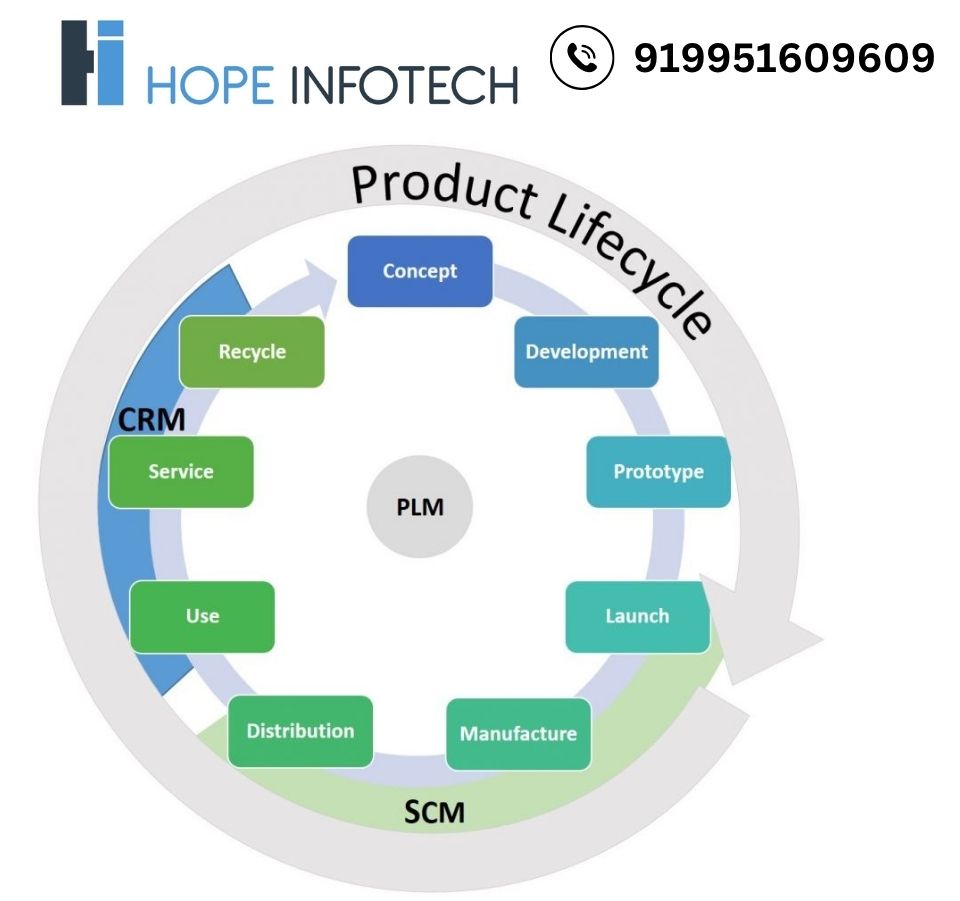

2. What is Product Lifecycle Management (PLM)?

PLM stands for Product Lifecycle Management, a strategic business approach that integrates people, processes, business systems, and information across the entire product lifecycle.

PLM Core Stages :

- Concept and Design

- Product Development

- Manufacturing

- Service and Support

- End-of-life

Teamcenter supports each of these stages, ensuring data consistency, traceability, and process efficiency.

3. Why Teamcenter? Key Benefits

Teamcenter is not just a data vault for product information — it’s a collaborative, flexible, and scalable PLM solution. Here’s why businesses choose Teamcenter:

1. Centralized Data Management

All product-related information is stored in one unified location, accessible across teams.

2. Faster Time-to-Market

Automated workflows and better collaboration speed up development cycles.

3. Cost Reduction

Reduced rework, streamlined change management, and better resource utilization lower overall product development costs.

4. Regulatory Compliance

Built-in traceability and documentation features support industry-specific compliance.

5. Secure Collaboration

Multi-level access control and audit logs ensure secure sharing of intellectual property.

Hope Infotech: Your Premier Teamcenter Training

At Hope Infotech, we take pride in offering job-oriented, hands-on Teamcenter online training tailored for beginners, professionals, and corporate teams. Our course curriculum is curated by certified industry experts with real-world implementation experience.

We ensure each learner not only masters the technical concepts but also gains practical exposure through live projects, case studies, and industry simulations.

4. Core Features of Teamcenter

Let’s dive deeper into what makes Teamcenter a robust PLM platform.

🔹 Product Data Management (PDM)

Manage BOMs (Bill of Materials), CAD files, documents, specifications, and more in a single repository.

🔹 Change Management

Track and control engineering changes through configurable workflows.

🔹 BOM Management

Manage multiple BOM views — engineering, manufacturing, service — ensuring consistency across the product lifecycle.

🔹 Document Management

Version control, permissions, and structured storage of all related documentation.

🔹 Visualization and Digital Mockup

View 2D/3D models directly in Teamcenter without needing native CAD tools.

🔹 Workflow and Process Management

Automate and enforce business processes with built-in workflow templates.

🔹 Requirements Management

Link requirements to products, ensuring end-user needs are reflected in design.

🔹 Integration with MCAD/ECAD

Out-of-the-box connectors for popular tools like NX, SolidWorks, AutoCAD, CATIA, and more.

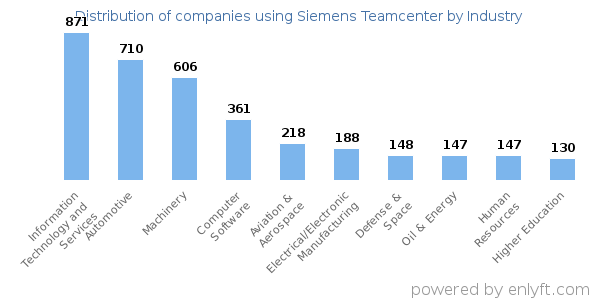

5. Industries That Use Teamcenter

Teamcenter is industry-agnostic and widely used across various verticals:

| Industry | Use Case Example |

|---|---|

| Aerospace & Defense | Design traceability, compliance documentation |

| Automotive | Integrated product design, supplier management |

| Industrial Machinery | BOM and configuration management |

| Electronics | ECAD-MCAD collaboration, rapid prototyping |

| Medical Devices | Regulatory compliance, quality control |

| Consumer Products | Time-to-market acceleration |

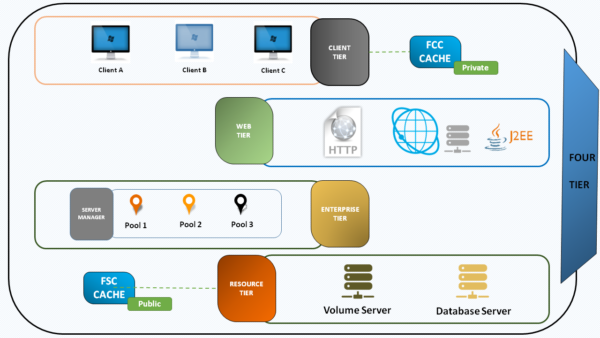

6. Teamcenter Architecture Overview

Teamcenter follows a three-tier architecture:

1. Client Tier

- Web-based thin client

- Rich client interface for power users

2. Middle Tier

- Application server hosting business logic

- Handles communication between the client and database.

3. Data Tier

- Oracle or Microsoft SQL Server as backend databases

- File Management System (FMS) for storing physical files

The modular and scalable nature makes suitable for both SMBs and global enterprises.

7. Teamcenter Integrations and Compatibility

Teamcenter can seamlessly integrate with other enterprise software such as:

- ERP Systems (SAP, Oracle, Infor)

- CAD Systems (NX, CATIA, Creo, SolidWorks)

- Manufacturing Execution Systems (MES)

- ALM Tools (Polarion)

- Office Suites (Microsoft Office, Google Workspace)

APIs and web services also allow for custom integrations, ensuring it fits well within your digital ecosystem.

8. Real-Life Applications and Use Cases

Case Study 1: Aerospace Engineering

A leading aircraft manufacturer used to manage 3D models, compliance documents, and product variants across international teams — reducing product errors by 30%.

Case Study 2: Automotive Supplier

An automotive supplier implemented for BOM and change management, cutting down production errors and accelerating prototyping by 40%.

Case Study 3: Medical Device Company

Teamcenter helped a medical device manufacturer ensure traceability and FDA compliance across its product development lifecycle.

9. Teamcenter Deployment Options

You can deploy Teamcenter based on your organization’s size and infrastructure preferences:

1. Teamcenter X (Cloud SaaS)

- Subscription-based

- Automatic updates

- Lower upfront investment.

2. On-Premises

- Full control over customization and data

- Higher initial setup and maintenance

3. Hybride

- Combination of cloud and on-premises for flexibility

10. Training and Certification Paths

To become a Teamcenter expert, there are multiple training paths:

1. Roles-Based Training :

- Teamcenter End Users

- System Administrators

- Customization & Development (ITK, BMIDE, SOA)

2. Certification Options:

- Siemens Certified PLM Professional

- Third-party platforms (Coursera, Udemy, etc.)

3. Institutes Offering Training:

- Siemens Learning Advantage

- Hope Infotech (India)

- Local engineering colleges and training centers

11. Challenges and How to Overcome Them

Despite its benefits, Teamcenter comes with challenges:

1. Complexity

It can be overwhelming for new users. Solution : role-based training and user-friendly UI customizations.

2. Migration from Legacy Systems

Data migration can be time-consuming. Solution: Use Siemens-certified migration tools and pilot testing.

3. Cost

Initial deployment can be expensive. Solution: Start with Teamcenter X or modular licensing.

12. Teamcenter Roadmap and Future Trends

Siemens is investing heavily in innovation, with the future of Teamcenter heading toward:

1. AI-Driven PLM

Predictive analytics, AI-based product insights, and design recommendations.

2. Integrated Digital Twin

Linking product, process, and performance data for real-time simulation and feedback.

3. Low-Code Customizations

Teamcenter now supports Mendix for rapid application development.

4. Extended SaaS Offerings

Teamcenter X is evolving to serve more industries with scalable cloud-native capabilities.

13. Conclusion

Teamcenter is more than just a PLM tool — it’s a strategic enabler for digital transformation. From improving collaboration to streamlining engineering workflows, it helps companies deliver better products faster and smarter.

Whether you’re looking to adopt PLM for the first time or upgrade your existing processes, offers a future-proof solution backed by Siemens’ engineering excellence.

14. Frequently Asked Questions About Teamcenter

1. What is Teamcenter?

Teamcenter is a product lifecycle management (PLM) software developed by Siemens. It helps organizations manage product data, processes, and collaboration across the entire product lifecycle—from design to production and support.

2. Who uses Teamcenter?

Teamcenter is used by engineers, designers, manufacturers, and product managers across industries like aerospace, automotive, electronics, industrial machinery, and medical devices.

3. What is the difference between PDM and PLM in Teamcenter?

PDM (Product Data Management) is a subset of PLM. While PDM focuses on managing CAD files and documents, PLM incovers the entire product lifecycle, including processes, workflows, BOMs, and change management.

4. Is Teamcenter cloud-based?

Siemens offers a cloud-based version called Teamcenter X, which provides all the core capabilities of with lower infrastructure costs and faster deployment.

5. Can Teamcenter integrate with other software like SAP or CAD tools?

Absolutely. Teamcenter offers out-of-the-box integrations with popular CAD tools (like NX, SolidWorks, CATIA) and ERP systems (like SAP and Oracle).

6. What is Teamcenter used for in manufacturing?

In manufacturing, Teamcenter is used for BOM management, change control, process planning, and ensuring product quality and compliance.

7. Is Teamcenter easy to learn?

While powerful, Teamcenter has a learning curve. However, with role-based training and a user-friendly interface, most users become proficient with consistent usage.

8. What are the training options for Teamcenter?

Training is available through Siemens Learning Advantage, authorized training institutes, and e-learning platforms. Options range from end-user basics to advanced customization and administration.

9. What programming languages are used for Teamcenter customization?

Customization often involves Java, C++, XML, and the use of Teamcenter’s ITK (Integration Toolkit), BMIDE, and SOA (Service-Oriented Architecture).

10. How much does Teamcenter cost?

Pricing depends on the number of users, modules, and whether you choose cloud or on-premises deployment. Siemens provides custom quotes based on business.